PCB fabrication is yet another vital process to follow. A proper choice of manufacturer would assist you in getting quality, competent, and reliable PCBs, which are much needed for the operation and service life of your electronic projects.

This article will highlight the key considerations when choosing the PCB fabrication manufacturer.

PCB Fabrication Fundamentals

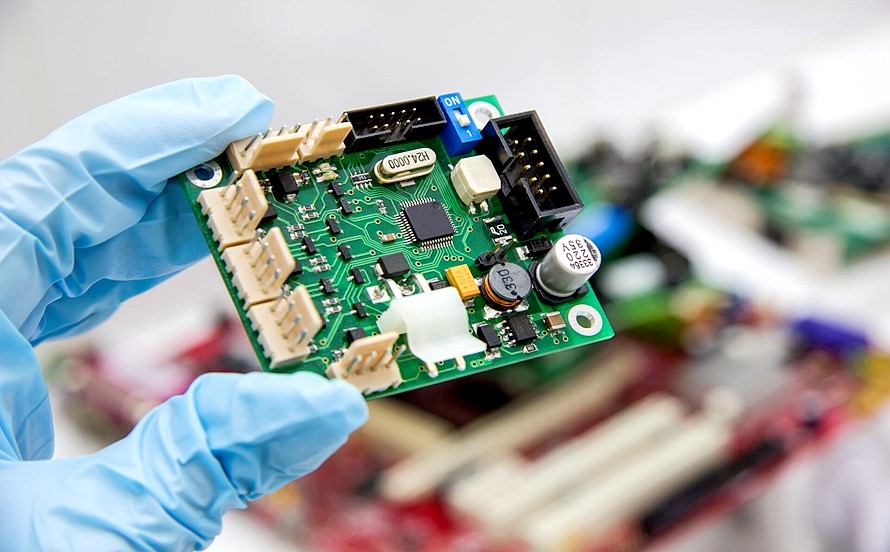

PCB manufacturing consists of manufacturing the physical boards that offer physical support to the electronic components and wire the components together. This generally involves designing circuit boards, etching copper foil, drilling holes, and placing multiple layers of finishing coat coverings.

PCBs have different types. These can be classified as single-sided PCB, double-sided PCB, and multi-layer PCB. A single-sided PCB has only one layer of copper foil.

Double-sided has two layers of copper sided (both on each side). Multilayer PCB on the other hand has more than two layers of PCB. The layers of PCB in multilayer can be changed depending upon the requirement.

Following are the considerations one must take into account when choosing the PCB fabrication manufacturer.

1. Evaluation of Capabilities of PCB Fabrication Manufacturer

More technological capabilities in your printed circuit board manufacturing company must be desired. Advanced technology, such as high-density interconnect (HDI) and flexible PCBs, will make it more practical to have a miniaturized, more flexible end-product design. Make sure that your PCB fabrication manufacturer is equipped with these latest technologies.

Ensure the manufacturer can operate under larger processes and various materials, such as FR4, Rogers, and polyimides. You must also examine their ability to work on challenging designs such as multilayer boards and complex layouts.

A technically skilled manufacturer can fulfill the specific requirements of your project, and you will get a good-quality, reliable, and operationally sound set of PCBs as per your specifications. That ensures that those electronic systems are working at their best and reliably.

2. Quality Assurance Standards

Quality assurance is a crucial demand in the PCB manufacturing process, and manufacturing standards such as the ISO 9001 and IPC standards evoke top-notch manufacturing. ISO 9001 assures that the PCB fabrication manufacturer adheres to strict quality management stipulations.

The IPC standards are the benchmarks of PCB design, performance, and reliability. The certifications are assurances that the manufacturer adheres to strict guidelines. To ensure compliance, ascertain the manufacturer’s certifications and audit reports.

Further, continuous improvement cases and customer feedback regarding quality problems should be ascertained. If one PCB fabrication manufacturer has complied with these standards, then your PCBs are reliable and durable, and they meet the industry’s best standards. Hence, you are assured of better and prolonged performance for your electronic products.

3. Customization and Flexibility

Customization in PCB manufacturing is essential to have the specifications that will meet the demands of your specific project. Some of the features that can be customized include the choice of the materials, which can include FR4, polyimide, or Rogers; the number of layers, which can be single-sided to multilayer boards; and the choice of the finish, which can include HASL, ENIG, or OSP.

By having this kind of freedom of various choices, you will have a solution designed to meet your project’s technical requirements and budget.

When considering a manufacturer, consider their capability of providing such customization and their experience in providing such bespoke solutions. Find a PCB fabrication manufacturer that is experienced in handling a range of projects and those that provide flexibility in design changes.

A good manufacturer with customizations will ensure that your PCBs are designed to meet your exact requirement specifications, leading to better performance and reliability of your electric devices.

4. Production Capability and Lead Times

Assessment of the production capacity of a manufacturer is essential to verify if they can handle the scale of your project. Production capacity includes the number of units the manufacturer can produce per given time and their capacity to scale up if required.

Lead times cannot be ignored, as production delays can affect your project schedules. Ask for the average lead times for different order quantities and levels of complexity.

Reliable and consistent delivery schedules are key to maintaining project speed and meeting due dates. Ensure the timely delivery track record and capacity of the PCB fabrication manufacturer to handle supply chain disruptions. Proper capacity and reliable lead times help keep your project on time and meet market demands efficiently.

5. Cost Considerations

Should one plan to start a project, it is crucial to know the cost factors involved in PCB manufacturing. These are key aspects that regulate prices: the type of material, the number of laminated layers, the size of the board, and the difficulty level.

Pricing is always important because while getting the most cost-effective product in its class is desirable, cheap solutions will likely result in sub-par build quality and functionality.

To get the right service price, be as precise as possible on your requirements and insist on the cost analysis. Precautions should be taken regarding charges that may not be immediately seen, such as setup charges, testing charges, and expedited shipping charges.

There are always options to compare the price for the calculated budget and get several offers from different producers. Clearness of price and all possible expenses is one of the issues to consider while choosing a more efficient and less risky solution.

6. Communication and Support of PCB Fabrication Manufacturer

The communication process is significant when sourcing a PCB manufacturer because it enables the identification of the manufacturer’s needs and comes up with probable challenges that may happen. Calculating the volume and accessibility of technical support by a specific manufacturer for a specific type of consumer can help conclude the level of a firm’s reactiveness.

In serious difficulty, a support team should report the problems in real time and offer live assistance if the situation warrants it. In this regard, if a PCB fabrication manufacturer offers you a project manager assigned to oversee your particular account for PCB, such circumstances will guarantee a smooth relationship and organization.

7. Reviewing Past Projects and Client Feedback

This indicates that a manufacturer’s history must be verified before determining its quality. See case studies, clients’ testimonials, and other perceptions that clients have about similar kinds of projects. Several examples of similar projects that contain the elements of difficulty, flexibility, and schedule you want for your own should be sought.

This means that subsequent purchases and positive remarks are reliable proof of a manufacturer’s trustworthiness and the quality of its products.

Record all the negative comments to identify possible problems and how they were addressed. Evaluating previous projects and customers’ feedback enables us to determine the most appropriate PCB fabrication manufacturer for quality and reliable printed circuit boards.

Our Capabilities as PCB Fabrication Manufacturer

Viasion develops and manufactures PCB fabrication as a globally famous manufacturer, providing you with a one-stop service for several project requirements.

Our products include the latest and most modern technologies, such as high-density interconnect (HDI) and flexible PCBs, which are standard and innovative.

The delivered thermally modified wood products and components may be customized according to the client’s preferences relating to material, layers, and finish.

Meeting the standards of quality to the optimum level possible and the maximum level, we are an ISO 9001-certified firm that provides you with nothing but the best. Our company has a large production capacity resulting from high capacity utilization and short lead times, ensuring timely delivery.

Lastly, at Viasion, we strive to ensure that we give the best customer support and consistency in the level of innovation we offer, making us your best choice whenever you need any PCB fabrication services.

Conclusion

The options when choosing the best PCB fabrication manufacturer involve capability, quality, customization, production capacity, cost, communication, performance history, geographical location, and innovation. After going through your study and analysis, make your decision.

The final output is reliable, with exceptional PCBs that will help you fulfil project requirements and make your project successful.