High-load exoskeletons straddle the boundaries of robotics, biomechanics and precision engineering. Such systems have to enhance human power, must spread weight effectively and be able to go through millions of cycles without disintegrating. CNC-machined parts form the core of this dilemma by addressing the dimensional accuracy where the durability must also be considered in the long run. Tolerance integrity is guaranteed by base machining, whereas fatigue, wear and corrosion are achieved by the surface treatments.

The production experts like the Wayken Rapid manufacturing take a major part in uniting precision machining with the high-end finishing processes. Their experience enables the designers to certify a prototype in a short period and produce at scale.

In this article, we analyze the context in which such complex CNC machining services can be used in collaboration with the surface treatment strategy to produce components with a potential to address the most severe demands of the high-weight exoskeletons.

Machining Precision as the Structural Foundation

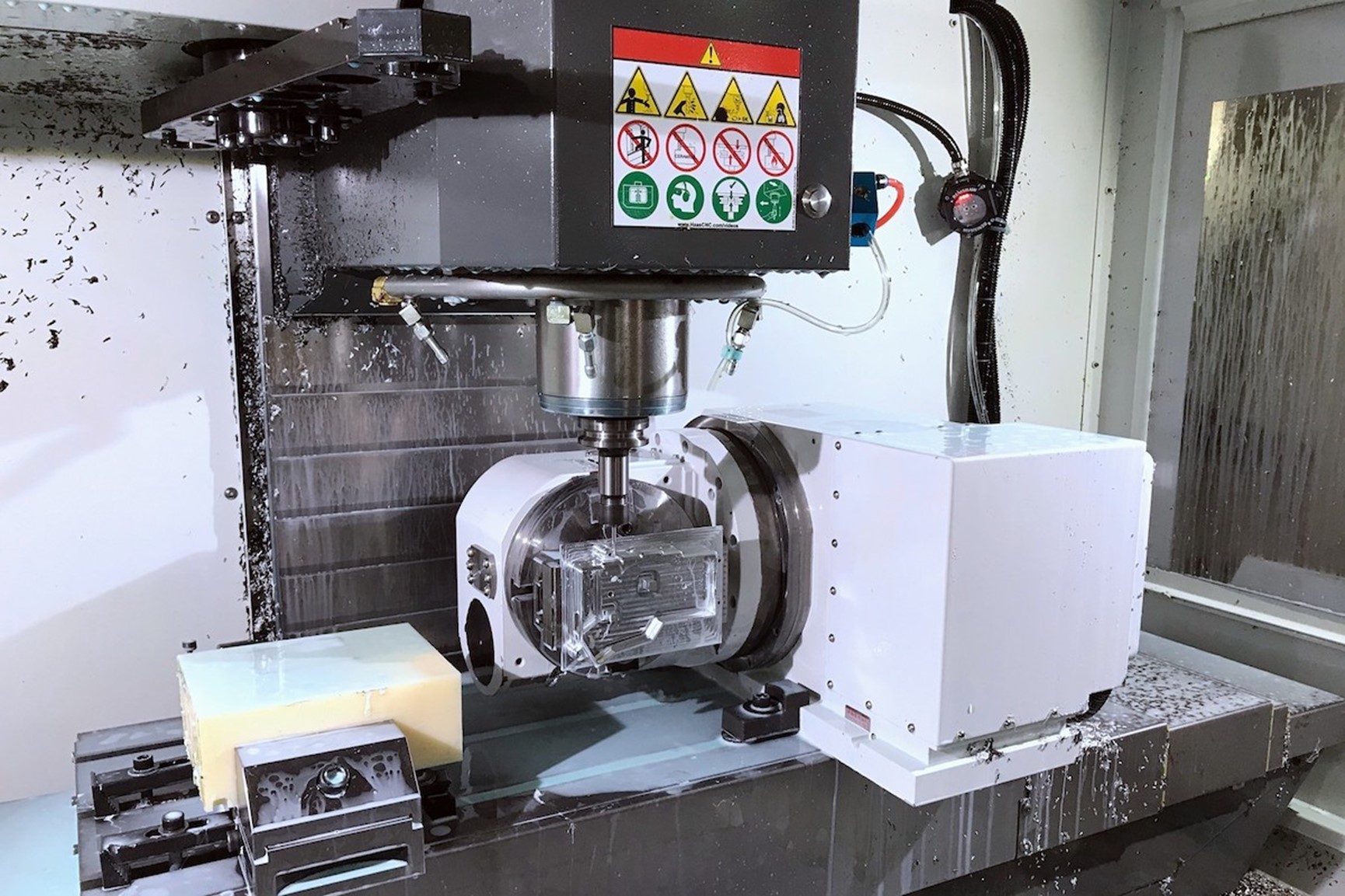

The structural components of exoskeleton are very vital to their performance. Joints, housings, and actuator mounts should be machined with precise tolerances such that forces are balanced and do not prematurely wear. With the five-axis platforms, microns of precision are attainable in concentricity, wall thicknesses and surface planar by use of CNC machining services. These capabilities guarantee stability even with high dynamic forces as in lifting, climbing or bearing weight.

Precision machining is more than ensuring a fit by reducing stress concentrations on key surfaces. The ability of engineers to control geometry at this micro level can avoid local strains that would otherwise result into premature fatigue. This type of structural reliability is what coatings and treatment should be erected on.

Treatments applied to the surface such as anodizing, hard coating, or plasma nitriding cannot be applied to anything but accurately machined bases and can do their best work only then. In the absence of such a foundation, the coating can crack or even wear out too soon. The machining and surface finishing processes are combined in high-load exoskeletons and are not discrete steps.

Surface Treatment for Performance and Reliability

Fit is guaranteed by machining accuracy; surface treatment guarantees a long lifetime. Components of high-load exoskeletons are subject to abrasion wear, corrosion from sweating, and articulation. The remedies are hence based on the underlying alloy. Typical examples of functions include hard anodizing of aluminum housings to form dense oxide films, plasma nitriding of titanium joints to harden surfaces and DLC coatings on steel couplings to reduce friction.

These processes make things harder, lower friction coefficients, and make components behave more consistently in long duty cycles. As an example, PTFE-impregnated hard anodized aluminum housings exhibit several-fold longer lifetimes as compared to untreated counterparts. When combined with strong surface engineering, the high-accuracy provided by precise geometry enables exoskeletons to achieve the high reliability required by the industrial and military sectors.

Durability Testing and Failure Mode Analysis

There is no guarantee of high-load exoskeleton systems reliability; it should be demonstrated. Fatigue and Durability testing is done by subjecting components to millions of load cycles, which simulate the forces in real-world motion. Through these trials, failures are found to have frequently started due to untreated surfaces, loci of machining marks or residual burrs. These low spots can be minimized by combining improved surface treatment, slowing down crack initiation and prolonging service life.

The most typical failure modes are surface fatigue, fretting wear at articulating joints and crack initiation utilizing corrosion. One requires a unique mitigation strategy. The dimensional congruency that is achieved through precision machining will be followed by specialized coating that is resistant to both wear and corrosion. Incremental deviations are identified within the real time inspection systems; thus failures do not lead to critical damages.

Validation is more than superficial testing. Sub-surface integrity is measured utilizing non-destructive evaluation methods (such as ultrasonic testing, CT scanning and laser metrology). When taken along with CNC machining services and powerful finishing services, the processes offer a basis to long-term endurance and dependability.

Scaling Production for Industrial and Defense Applications

The use of exoskeletons depends not just on its performance regarded as technical aspect, but also on a feasible manufacturing. The requirement of industrial programs are hundreds of the same high-quality components and tolerance stabilities in hard climate environments with the defense systems. The two challenges can only be met through highly evolved CNC machining services where automation is present in all the stages. Robotic loading/unloading, automatic tool changing and predictive maintenance cycles maintain throughput that is not sacrificed in terms of dimensional accuracy.

Scaling also relies on workflows of surface treatment. Autonomous anodizing, nitriding and coating systems ensure uniformity of performance with large runs of production. Processes are monitored robotically and they are uniform whereas digital twins, and sensors with connectivity to the IoT supply live data to machining centers. This is a closed loop that decreases downtime, enhances repeatability and lowers the manufacturing process as prototyping into full manufacturing.

During this stage, the existence of partnerships is essential. Wayken Rapid manufacturing is a linkage with the industrial implementation that provides collaborations with providers between the experimental validation and industrial implementation. Its integrated solution helps guarantee uniformity in quality at the production level so that exoskeleton systems are operationally and regulatory compliant.

Conclusion

High-load exoskeleton is based on surface-treated CNC components. The resulting dimensional accuracy is provided by CNC machining services, with state-of-the-art surface treatments being provided against wear, corrosion, and fatigue. All of these processes together form components that can survive millions of load cycles in harsh conditions. With machining, treatment, and durability testing as it expands to industry, healthcare and defense, it will continue to be a core part of reliability. Scalable manufacturing plans and reliable supply chains will make next-generation exoskeletons where the power of human nature can be blended with engineered strength and stamina- taking the performance bar to new heights.